Highlighted Projects

Our most valuable deliverable is our promise to complete what we start in the safest, most efficient manner with the high quality possible. Our team provides the cost-efficient services of a small company with the dependability, safety, quality, and management of a large company. As a small business, we are acutely aware of the value of our repeat customers and make it a priority to fulfill their goals for specific projects. We ensure the superiority and professionalism of our staff with personal oversight by our corporate management team.

At RELYANT Global, we maintain a comprehensive safety and quality assurance monitoring program for all projects. This includes a Corporate Environmental Safety and Health Plan, Accident Prevention Plans, Activity Hazard Analysis Plans, and Quality Assurance / Quality Control Plans. We provide technical experts on all of our sites to monitor, inspect, and report potential issues to the corporate office, ensuring that all that work is conducted in accordance with international quality and safety standards.

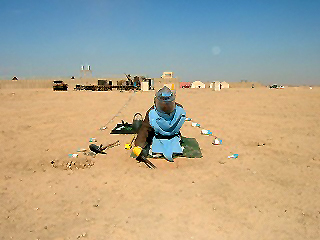

AED-S Mine Clearance MATOC

RELYANT Global has performed the site assessment and clearance of over 10,000 acres of land, contaminated with MEC (rockets and artillery projectiles (up to 120mm), mortars, grenades, aerial bombs, improved conventional munitions (aerial bomblets) across southern and Western Afghanistan. We have been awarded and completed 30 task orders (over 80% of all contracted work) to date under this MATOC contract.

WERS Demining Task Order (subcontractor to ECC)

RELYANT Global’s team of 200+ personnel performed demining and battle area clearance for over 200,000 square meters of land at Bagram Air Field, Afghanistan. RELYANT Global provided donor explosives and storage facilities, communication support for all project activities, armored MHE, PPE, transport vehicles, and mine detection instruments. Additionally, we provided a qualified medical staff and medics/paramedics in accordance with IMAS and AMAS standards.

Bagram Warehouse Facilities

RELYANT Global is currently using light steel frame construction to efficiently build four (4) high quality structures in the volatile conditions of Afghanistan providing the US Government both cost and time savings. Light steel frame construction methodology is ideal for high volume manufacturing of residential housing, warehouses, training facilities, multi-story commercial buildings, and other billeting support needed at military facilities around the world due to its innate accuracy and design capabilities.

Afghanistan Spray Insulation Project (ASIP)

RELYANT Global was contracted to spray foam insulation to temporary structures, canvas and thin skin facilities throughout Afghanistan – a combined surface area of over approximately four million square feet. The foam insulation provides soldiers comfort during extreme hot and/or cold weather.

Al-Anbar Province Vehicle Maintenance

Al-Anbar Province Vehicle Maintenance

RELYANT Global provided life support, logistical support and complete project management for fleet vehicle maintenance to the Al Anbar Provincial fleet. We provided convoy, and personnel security operations for MSTC-I approved, Mobile Maintenance Teams. RELYANT successfully completed over 85 mobile maintenance missions, repairing over 250 vehicles at 47 outlying FOBs throughout Iraq.

Modular Relocatable Buildings (RLBs)

Modular Relocatable Buildings (RLBs)

RELYANT Global was providing the US Forces in Afghanistan with re-locatable, modular buildings (RLBs). The first delivery order is for manufacture, delivery, construction and installation of 15 RLBs. Individual RLB modules are manufactured to the Government’s standard design, for ease of relocation, and reconfiguration for new missions.

Bagram Airfield Deconstruction MATOC: Task Order 001 – Relocating RLBs

Bagram Airfield Deconstruction MATOC: Task Order 001 – Relocating RLBs

For this contract, RELYANT was responsible for the mutilation of a roofing system, metal stairs, a metal platform, and miscellaneous building utilities and site utility disconnections for sixteen (16) RLB containers at Bagram Airfield. RELYANT accomplished this work by using oxygen/acetylene gas cutting torches, plasma cutting torches, and angle grinders.

“Your workers did a quick, clean and safe job relocating the RLB’s and also did the best work of anyone fixing the beaching in the manholes.”

-Darryl G. Knowles, Civ, DAF, COR